|

After a considerable break from model building, and somewhat

impoverished, I was horrified to find that the price of

covering material appeared to be prohibitive. Various plastic

coverings seemed to start at $30 a roll, and that neither

wide nor long!

As a student of the Reverend F. Callon’s book, “ABC

of Aeromodelling” (or was it “Aeromodelling

for Beginners”?), I have always been a stick and tissue

man. Tissue was easy to apply. Just paste it on with boiled

flour or “Clag”, water-shrink it and then apply

Dope, being sure to pin the wing down at each operation

to avoid warps. Many colours and different weights of tissue

were readily obtained and of reasonable cost. “Modelspan”

was my favourite, which I believe was an English brand:

American tissue was also there to be had, but it didn’t

shrink the uniform way the “Modelspan” did.

Up until recently, I had quite a library of tissues, but

these disappeared or were used up rather too quickly. So

it was off to find some tissue from the Hobby Shop. Shock

Horror, it was $4.50 for a single sheet! It was going to

cost me the best part of $50 just for the tissue on a large

F/F wing! Outrage! Considering I often fly over wheat stubble,

this was as expensive as yachting! The new plastics resist

puncture, but I did not like their properties at all. My

structures required a taught covering for their strength,

and the plastics did not have it.

At the 1971 Nats in Northam, WA, final round of A/2, Mike

Pettigrew only needed 120 seconds to beat me out of first

place. At 110 seconds, he was still 50’ up and I was

a gone goose. But then his plastic covered wingtips suddenly

fluttered, and his model dived into the ground to give me

the win! So much for plastic (and divine intervention!).

After the 2005 Australian F/F Champs, I found myself in

Canberra, visiting my sister Isobel. For some reason, we

visited a textile/fabric shop and there to my joy and amazement

I found what appeared to be a roll of heavyweight black

tissue! It looked the same, random weave, and ripped just

the same as tissue. It was in fact Vilene, a plastic concoction

used by dressmakers. It was never going to water shrink,

but the open weave suggested that it would certainly shrink

when doped. However, its big selling point was the price:

$5 per square meter, just a fraction of the price of tissue

and plastic.

I bought 5 metres each of black and white and put them to

one side, in my pile of useful-in-the-future items. Recently,

I visited another fabric shop, this time Textile Traders

in Perth, and found lightweight Vilene at $3 for 5 metres

(!) on special.

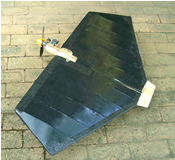

Now I was ready to cover my proof-of-concept new F2B design,

and I wanted it to be black. Perhaps this was the time to

drag out the heavyweight Vilene from Canberra. The new design

had carbon-capped ribs for rigidity, the carbon glued on

with balsa cement rubbed through a single 12K roving. Not

a very neat arrangement, but it meant I could glue the Vilene

direct to the cap strips, again with balsa cement (Aeroflyte

C23). This also meant I could dispense with spars, as the

glued-on covering held the long, slender ribs in place very

nicely.

Now this is where the trouble started. I has no idea how

much the doped and painted covering was going to weigh.

However, as this design had no fuselage, flaps or tailplane,

I figured I had some room for manoeuvre with respect to

weight. In fact, the completed airframe with engine was

only 32oz, less than half that of my poor old test-ship

Firecracker. This is how the weight story emerged.

The bare airframe weighed 556g. After gluing on the Vilene,

and using the best part of 2 tubes of C23 in the process,

the weight was up to 605g. One coat of Dope disappeared

into the Vilene like a camel into quicksand, bringing the

weight up to 635g. A second coat likewise disappeared, for

a weight of 650g.

This was getting out of hand, so I figured to finish the

job with a thick coat of Feast-Watson polyurethane. This

brought the weight up to 682g: but this too disappeared

into the quicksand, so that another coat was needed and

the fat old camel was up to 712g! Now this was a worry,

as most of this was going behind the C/G, so I quit, leaving

the surface finish with as much gloss as a shagpile carpet.

It looked OK from about 3 metres away, so at least if I

hid it from the stunt judges prior to the contest they wouldn’t

know any better.

Certainly the covering was drum tight. In fact, as soon

as I started the motor the whole shebang sounded like a

drum being pounded at 7000 belts per minute! Never mind,

perhaps it would sound OK in the air. Well, its gale force

winds and rain as I write this, so the reader will have

to wait to see how the model flew. And of course, if it

flies badly, you won’t hear another peep from me!

Now here is the rub. That model has a 700 square-inch wing.

The covering weighed 156g and would have been more if I

had of persisted in getting a nice finish. But the Vilene

cost less than $3, the dope was about $10, the C23 about

$10, and the polyurethane about $4.

The weight would have been a lot less if I had used the

lightweight Vilene. My micrometer gave the thickness of

the heavyweight Vilene as .0055”, while the lightweight

was .0035” (the purchase docket showed “Vilene

Tracing 1200”). I should have used the latter, but

it was white. I should mention that the material also could

be heat shrunk. I used my Ozito heat gun to shrink it, then

doped more-or-less straight away. Rip-stop nylon kite and

sailcloth, also heat-shrink, but quickly go slack again

when they cool (also they cannot be doped).

So what the heck is Vilene used for? Well some time back

my Rosie made a silk wedding dress for her daughter: some

6 months later, after the baby was born, we were still picking

bits of silk out of the carpet. The stuff just falls to

bits when you cut it out. The idea with Vilene is that you

don’t cut the silk out at all: you just back it with

the Vilene and sew right thru the lot, with the pattern

marked on the Vilene. Then the Vilene can just be pulled

out from under the stitches, as it falls to bits, just like

ripping tissue paper.

Next time, I shall use the lightweight material. The Haberdasher

tells me it comes in a number of grades, so it might be worth

trying to find something lighter again. Well worth a try.

|